Home > Inks

Similar with original ,DBK is more deeper than original ink.

Made of imported special developed reactive dye dispersion for digital textile printing

Good stability, high dyeing rate, vivid color

Excellent fluency ability,keep stable head status after long time printing.

Directly printing, no hand-feeling, meeting the digital textile printing mass production

Washing fastness 4-5 grade, dry rubbing fastness 4-5 grade, wet rubbing fastness 3-4 grade, light fastness 4-5 grade

| Printhead model | BK | C | M | Y | LC | LM | OR | R | B | GY | Fluorescent M | Fluorescent Y | flush | |

| Epson | DX5/TFP/DX7 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| I3200 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 5113/4720 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| S3200 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| Industrial | Kyocera | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Starfire | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| Ricoh | √ | √ | √ | √ | √ | |||||||||

| Konica | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

1.Temperature:23-29℃

2.Humidity:above 55%. (the best condition is 24-28℃,humidity 60-70%)

Storage Suggestions:

3.Sealed well and kept in conditions with 15-25℃,40-60%

4.sealed and stored 9 months , once opened should be used within 1 week. Avoiding the sunshine , can’t be mixed with other solvents

Package volume offering:500ml 1L 5L 20L

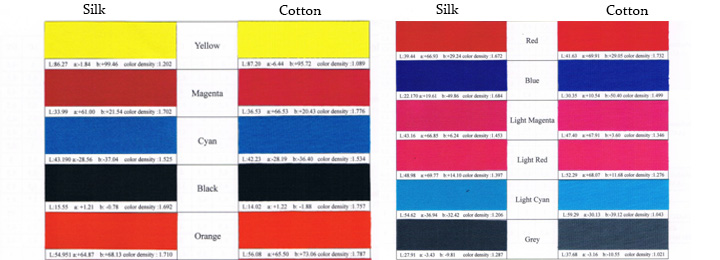

Color density testing

| Phisical and chemical parameter data standard | ||||

| Ink model |

PH |

conductivity(uS/cm) |

viscosity(cp 25℃) |

Surface tense(mN/m) |

| BK |

6.65-8.9 |

≤15000 |

3.35-4.0 |

24.7-29.5 |

|

C |

7-9.8 |

≤10000 |

3.17-3.81 |

25.2-29.8 |

|

M |

7-9.8 |

≤10000 |

3.20-3.81 |

26.7-32.0 |

|

Y |

7-9.8 |

≤10000 |

3.20-3.81 |

26.2-30.5 |

|

OR |

7-9.8 |

≤10000 |

3.20-3.86 |

26.2-31.5 |

|

B |

7-9.8 |

≤10000 |

3.35-3.95 |

29.7-36.5 |

|

R |

7-9.8 |

≤10000 |

3.20-3.86 |

26.7-32.0 |

|

GY |

7.2-8.9 |

≤4000 |

3.05-3.70 |

27.2-32.5 |

| SGS test data(AATCC) | |||||||||

| Color | C | M | Y | K | OR | GY | B | R | |

| Color fastness to laundering | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | |

| Color fastness to perspiration | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | |

| Color fastness to light | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | |

| Color fastness to crocking | Dry crocking | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 |

| Wet crocking | 4 | 4 | 4 | 3.5 | 4 | 4.5 | 4 | 3.5 | |

| Reactive ink AATCC standard testing result | ||||||||||||||

|

Color/Fastness |

Laundering(50℃)test |

perspiration resistance test |

Dry crocking test |

Wet crocking test |

Light test |

PH test |

formaldehyde content test |

|||||||

|

|

Cotton |

Silk |

Cotton |

Silk |

Cotton |

Silk |

Cotton |

Silk |

Cotton |

Silk |

Cotton |

Silk |

Cotton |

Silk |

| Cyan |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4 |

4 |

4.5 |

4.5 |

7.3 |

7.3 |

N.D. |

N.D. |

|

Magenta |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4 |

4 |

4.5 |

4.5 |

7.3 |

7.2 |

N.D. |

N.D. |

|

Yellow |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4 |

4 |

4.5 |

4.5 |

7.2 |

7.3 |

N.D. |

N.D. |

| Black |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

3.5 |

4 |

4.5 |

4.5 |

7.1 |

7.1 |

N.D. |

N.D. |

|

Blue |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4 |

4 |

4.5 |

4.5 |

7.3 |

7.2 |

N.D. |

N.D. |

|

Red |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

3.5 |

4 |

4.5 |

4.5 |

7.2 |

7.4 |

N.D. |

N.D. |

|

Orange |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4 |

4 |

4 |

4 |

7.3 |

7.4 |

N.D. |

N.D. |

|

Grey |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

4.5 |

7.1 |

7.2 |

N.D. |

N.D. |

Send us a message

If you have any suggestions or opinions about our products, please leave a message. We will immediately answer your questions. Thanks for your support!